Airlock systems are integral to various production procedures, delivering an efficient barrier in opposition to contaminants and cross-contamination.

Airlocks in many cases are Outfitted with features for instance air showers, which use large-strain jets of air to remove dust and also other particles from garments and devices right before moving into the clean place.

Usually, doorways on either side with the airlock are interlocked to avoid them from getting opened concurrently, keeping the pressure differential and making sure the containment of contaminants.

The doors can also be Geared up with sterilization mechanisms for instance ultraviolet (UV) lights or hydrogen peroxide (H2O2) vapor systems to reduce any microorganisms existing within the surfaces of resources or machines just before they enter the thoroughly clean area.

Cascade Airlock: These airlock are quite common getting increased tension on a single aspect and reduce strain on A different side. With this system positive air strain flows from the higher force internal zone to become airlock and through the airlock towards the lesser reduced strain quality space.

Air Showers are specialised decontamination systems built-in into airlocks to reinforce cleanliness in advance of coming into controlled environments.

Their interlocks prevent both doors from getting opened at this exact check here same time, which may cause cross-contamination.

Utilized being a A part of, spots exactly where the merchandise requires insurance policy and the final population outer into the cleanrooms demand assurance from the merchandise, to decrease the chance of sensible expressive from moving into the lesser pounds clean up-room. Place, as an example, bigger energy, exacerbating regions terminal sanitization isn’t a choice.

The principle guiding a sink airlock is simple. By protecting decrease tension inside the airlock than in adjacent spaces, air flows from the upper-stress zones, preventing contaminants from escaping into cleaner or fewer contaminated locations.

This can be obtained by managing the airflow concerning adjacent rooms, making certain that air moves from cleaner parts to less thoroughly clean types, or through the use of barriers to isolate the two environments.

-Each doors of airlock really should not be opened at the same time. To start with open up a single doorway and enter into airlock from Course D then shut that doorway and open up other door to enter into Class C.

In this type of situation it is apparent that 20 Air changes is probably not enough to maintain Quality C more info requirements as several particulates are produced by several operations like debagging, disinfecting and so forth.

-checking of air pressure is required in all regions since any fall or rise in the force of any area may lead to cross-contamination.

This technique of air force Command is extremely productive in making sure that contaminants from considerably less clean up areas will not enter cleanrooms Which particles created within the cleanroom do not escape to bordering environments.

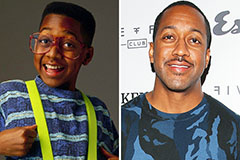

Jaleel White Then & Now!

Jaleel White Then & Now! Kel Mitchell Then & Now!

Kel Mitchell Then & Now! Yasmine Bleeth Then & Now!

Yasmine Bleeth Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!